PLA and PLA+ are two very similar – and very popular – materials for FDM 3D printing. However, there are several key differences between the materials that are good to know. This comparison will help you choose which material to use for your 3D-printed custom parts.

What is PLA?

PLA (polylactic acid) is a thermoplastic that is commonly used in 3D printing. It is made from the fermented sugars of plant-derived materials such as corn starch or sugar cane, and is biodegradable, recyclable, and compostable.

The properties of PLA include the following.

-

High stiffness. PLA is stiff and brittle when compared to materials such as ABS or PETG. This means it is not always suited to parts that require high degrees of flexibility.

-

Good strength. PLA is a relatively strong material, featuring a flexural strength of 103 MPa.

-

Low melting point. A melting point of approximately 145 °C makes PLA well-suited for 3D printing.

-

Fine details. PLA material can be used to create parts that exhibit fine details, although a minimum feature size of 1.2 mm is recommended.

-

Low UV and temperature resistance. PLA will quickly deform under high temperatures and UV light.

-

Chemical resistance. PLA is fairly chemical-resistant and is not soluble in certain solvents (such as isopropyl alcohol). However, certain chemicals can cause it to release lactic acid, which can be harmful in large quantities.

What is PLA+?

PLA+ is an enhanced version of PLA that has been formulated to exhibit better mechanical properties. To create PLA+, manufacturers add additives to regular PLA during polymerization.

What’s the difference between PLA and PLA+?

PLA and PLA+ are very similar. That said, their key differences lie in their mechanical properties and performance characteristics. These include the following.

-

Flexibility and brittleness. Standard PLA is known for its stiffness and brittleness (i.e. a low impact strength). It can be somewhat prone to breaking under stress. PLA+ is formulated to be less brittle and more flexible.

-

Strength. PLA+ is designed to have increased strength, providing improved durability and resistance to breaking.

-

Temperature resistance. PLA+ may exhibit slightly better resistance to high temperatures and UV light than PLA.

What are the disadvantages of PLA+?

PLA+ outperforms PLA on most metrics. However, there are two notable disadvantages of the material that merit some consideration. Let’s take a look at them.

-

Cost. PLA+ tends to be more expensive than standard PLA due to the addition of modifiers and enhancements.

-

Print difficulty. PLA is known for its ease of use. However, PLA+ may require higher print nozzle and print bed temperatures – making it a bit more difficult to print with than PLA.

What are the advantages of PLA vs. PLA+?

Sometimes, you may not need the improved characteristics of PLA+. In these situations, PLA can still serve you well. Here are a few situations and reasons as to why you might select PLA over PLA+.

-

Cost considerations. If budget constraints are a primary concern and the enhanced mechanical properties of PLA+ are not crucial, standard PLA may be the better choice.

-

Simplicity and printability. PLA adheres well to build surfaces, has minimal warping, and generally requires less fine-tuning of printing settings. This makes PLA a preferred choice for beginners or those who prioritize hassle-free printing.

-

Wide availability. Standard PLA is widely available and comes in a variety of colors and formulations. This availability can be advantageous for users who need a specific color or property readily accessible.

-

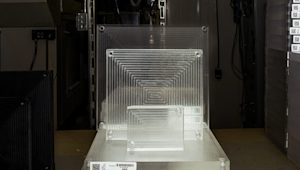

Non-functional prototypes. PLA may be a suitable and practical choice for prototypes that do not need to function. It is also a popular material for general-purpose 3D printing.

What are the advantages of PLA+ vs. PLA?

PLA+ is often favored in scenarios where increased strength, reduced brittleness, and improved flexibility are critical factors. Users should consider the intended application, print characteristics, and desired material properties when making the decision. These could include the following.

-

Functional prototypes. PLA+ is preferred for prototyping applications where increased strength and durability are essential, offering improved mechanical properties over standard PLA.

-

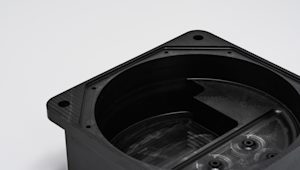

End-use parts. PLA+ is suitable for creating functional parts that require enhanced strength and reduced brittleness, making it useful in engineering and manufacturing applications.

-

Mechanical components. Applications requiring higher flexibility and impact resistance, such as gears and mechanical components, benefit from PLA+'s improved mechanical properties.

Surface finishes and post-processing for PLA and PLA+

PLA and PLA+ are known for their smooth surface finish, but post-processing techniques can further enhance the appearance of printed parts. Here are a few of the surface finishes and post-processing methods for PLA and PLA+ that our customers commonly use.

-

Sanding. Sanding is a versatile technique that can be used to smooth out layer lines and imperfections on both PLA and PLA+ surfaces. Starting with coarse grits and progressing to finer grits can achieve a polished finish.

-

Priming and painting. Both PLA and PLA+ are receptive to primers and paints. Applying a primer can create a smoother surface, and painting allows for customization with various colors and finishes.

-

Epoxy coating. Applying a thin layer of epoxy resin can provide a glossy and protective finish to both PLA and PLA+ prints, enhancing their appearance.

-

Polishing. Parts created with PLA and PLA+ can also be polished using a buffer to create the smoothest possible surfaces.

Produce custom PLA parts

Order 3D printed parts using PLA. Just upload a CAD file to receive instant pricing and lead times. To get your 3D printed project started, you can also read more about choosing the right materials for your application and our guide to plastics.

Frequently asked questions

Is PLA environmentally friendly?

PLA is derived from renewable resources and technically biodegradable, although it may take a long time to biodegrade.

How does PLA+ differ from PLA?

PLA+ has enhanced strength and flexibility compared to standard PLA.

Can PLA+ be used in 3D printing?

Yes, PLA+ is commonly used for 3D printing, offering improved mechanical properties, although it may require higher printing temperatures.

Is PLA or PLA+ more expensive?

PLA+ is usually more expensive due to added modifiers and enhancements.

Are PLA and PLA+ easy to sand?

Yes, both PLA and PLA+ can be sanded to achieve smoother surfaces.

Can PLA and PLA+ be painted?

Both materials can be primed and painted.

Are PLA and PLA+ heat-resistant?

Both have low heat resistance, however PLA+ may show better resistance to high temperatures compared to standard PLA.

Is PLA+ suitable for outdoor use?

PLA+ is better suited for outdoor applications due to improved UV resistance.

Do PLA and PLA+ require a heated bed for 3D printing?

A heated bed is not strictly necessary for PLA or PLA+, but PLA+ often requires higher printing temperatures – for which a heated bed can be beneficial.

Can PLA and PLA+ be used for functional parts?

PLA+ is preferred for functional parts due to its enhanced strength and durability. Standard PLA is suitable for less demanding applications.