What are legacy parts?

The term “legacy parts” refers to outdated or obsolete components or equipment that are no longer commonly used or manufactured. However, they may still be in service due to the need to maintain older machines or support existing manufacturing processes.

What industries use the most legacy parts?

Several industries still heavily rely on legacy parts due to the longevity of their equipment and the need to maintain older systems. Some of the industries that use the most legacy parts include the following.

-

Aerospace and defense. Aircraft and military equipment often have long service lives, and maintaining their operational capabilities requires sourcing and using legacy parts such as mechanical flight control components and older engine parts.

-

Automotive. Classic cars and older automotive models may require legacy parts such as carburetors, ignition points, and mechanical fuel pumps.

-

Energy and utility. Power plants, electrical grids, and other utility infrastructure can have equipment with long lifespans, necessitating the use of legacy parts such as turbine blades, switchgear, and electrical relays.

-

Industrial manufacturing. Certain industrial machinery and equipment may continue to be used for extended periods, relying on legacy parts like ball bearings and mechanical gears, for repairs and replacements.

-

Healthcare. Medical devices and equipment, particularly in fields such as radiology or diagnostics, can have long life cycles, requiring access to legacy parts such as X-ray tubes and analog sensors for repairs.

-

Railway transportation. Railway transportation systems often have long service lives, leading to the need for legacy parts such as signaling equipment, brake systems, and lighting fixtures for safe and reliable operation.

What challenges do legacy parts pose to businesses?

Because legacy parts are hard to find or are no longer in production, replacing them can be costly and time-consuming. The ability to manufacture replacement legacy parts allows businesses to continue functioning without significant disruptions or the need for a complete overhaul in terms of processes or machinery.

Using reverse engineering to manufacture legacy parts

Creating “new” legacy parts often requires reverse engineering of an existing legacy part. To do so, you can follow these general steps.

-

3D scanning: Use 3D scanning technology to create a digital 3D model of the legacy part. This can be done through methods like laser scanning or structured light scanning.

-

Create a CAD Model. Convert the 3D scan data into a CAD model using specialized software. This CAD model represents the geometry and dimensions of the legacy part.

-

Material analysis. Identify the materials used in the legacy part. Material testing and analysis may be required to determine the mechanical properties of the original material.

-

Functional analysis. Study the functionality and performance of the legacy part. This involves understanding how the part interacts with other components and the overall system.

-

Identifying manufacturing methods. Investigate the manufacturing processes used to create the original legacy part. This information helps in selecting appropriate modern manufacturing methods.

-

Prototyping and testing. Create prototypes of the reverse-engineered part using the CAD model. Test the prototypes to validate their performance and functionality.

-

Refinement and optimization. Fine-tune the reverse-engineered design based on test results and feedback. Optimize the design for manufacturing, cost, and performance.

-

Production. With the final reverse-engineered design and documentation, begin production using modern manufacturing methods and materials.

Selecting materials for legacy parts

The materials used to create legacy parts will vary depending on the type of component and its intended application. However, you don’t have to use the same material from which your legacy part was originally manufactured. In fact, it may be better to use a different, more modern material that features similar or higher-performing properties to the original.

Some common materials used to create replacement legacy parts include:

-

Metals. Various types of metals such as steel, aluminum, copper, brass, bronze, and nickel alloys are commonly used for mechanical and electrical components.

-

Plastics. Different types of plastics like polyethylene, polypropylene, nylon, and polycarbonate are often used for non-metallic parts.

-

Composites. Composite materials, which are combinations of two or more materials, can provide specific properties suited for particular applications.

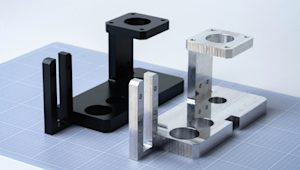

Manufacturing methods for legacy parts

Because modern manufacturing technologies have significantly changed over time, some legacy parts may be challenging to reproduce using the original method. This could be due to changes in materials, production techniques, or the availability of skills involved in older manufacturing processes. However, here are a few common manufacturing methods for legacy parts that are still commonly used today.

-

CNC machining. Legacy parts that were made from metals or other machinable materials may have been produced through various machining processes, such as milling, turning, drilling, and grinding.

-

Casting. Casting processes such as die casting are often used to create parts made of metals or certain alloys. One-off replacement parts for these can be produced by various machining techniques which match what most casting shapes offer.

-

Injection molding. For legacy parts made of plastic or certain polymers, injection molding is a common method for mass production. To replace small volumes of injection molded parts, CNC machining or even 3D printing is usually preferable.

-

Welding and joining. Assembling parts together through welding, brazing, or soldering was commonly used in legacy manufacturing.

-

Additive manufacturing. While 3D printing is a comparatively new technology, it is useful for creating reverse-engineered prototypes to test a part’s functionality before use. Certain 3D printing technologies are also excellent for replacement production parts.

Design for manufacturability and legacy parts

Design for manufacturability involves optimizing the design of a product to facilitate efficient and cost-effective manufacturing. When dealing with legacy parts, it requires adapting designs to accommodate older manufacturing techniques, materials, and equipment.

Here are a few tips for using DFM analysis to minimize the costs of your legacy parts.

-

Compatibility with existing equipment. When incorporating legacy parts into a new design, it is essential to ensure compatibility with existing manufacturing equipment and processes. This may involve designing components with the same dimensions or interfaces to fit seamlessly with older machinery.

-

Manufacturability constraints. Legacy parts may have been manufactured using older techniques that are no longer cost-effective or efficient. Designers should consider the limitations of legacy manufacturing methods and adapt the design to accommodate them. Certain manufacturing methods used in production-quantity runs are not necessarily suitable for low volumes of spare parts. Instead, choose the manufacturing method to match the volume of parts.

-

Lifecycle planning: Since legacy parts may eventually become obsolete or difficult to source, designers should consider incorporating provisions in the design for future replacements with more modern alternatives.

-

Standardization: Where possible, standardize legacy part designs to minimize customization and reduce manufacturing complexity. This can help lower costs and lead time.

-

Material substitution: Identify modern materials that can serve as suitable replacements for the original legacy materials. Look for materials that offer similar properties but are more readily available and cost-effective.

-

Batch manufacturing. Group similar legacy parts into production batches to take advantage of economies of scale and reduce setup times and costs.

-

Lean manufacturing principles. Implement lean manufacturing principles to eliminate waste, reduce inventory, and improve overall efficiency in the production process.

-

Inventory management. Maintain an inventory of critical legacy components and materials to reduce lead time and ensure a more consistent supply chain.

Get custom legacy parts into production

Keep machines running for many years to come by ordering custom legacy parts with Protolabs Network. Get an instant quote and free DFM feedback by uploading your CAD file.

You can learn more about manufacturing techniques, including tips for producing end-use parts and how to select the right material for your project.

Frequently asked questions

Why are legacy parts important?

Legacy parts support existing infrastructure, ensuring operations continue without significant disruptions or expensive upgrades.

Which industries use legacy parts the most?

The aerospace, automotive, energy, industrial manufacturing, healthcare, and railway transportation industries often use legacy parts.

What materials are commonly used to manufacture legacy parts?

Metals, plastics and composites are all commonly used to create legacy parts.

What affects the cost and lead times for legacy parts?

Manufacturers can optimize materials and processes, standardize designs, use batch production when possible, and collaborate with suppliers.

Why is reverse engineering important for legacy parts?

Reverse engineering allows recreating designs for components that are no longer available, enabling their production using modern methods and materials.