The challenge

SnorriCam develops customizable, professional camera rigs that attach to actors to get dynamic and immersive point-of-view shots. As a customizable, complex and niche industry product, the rig is constantly undergoing design iterations, and the device itself comprises a huge number of metal parts that need to fit together perfectly. Traditional manufacturing slows down the design process, and even finding manufacturers to produce tiny numbers of specialized parts is tricky.

How we helped

Our quote builder and service offerings helped SnorriCam transform the first professional iteration of the rig into a robust piece of filmmaking equipment. Being able to compare many quotes instantly allowed SnorriCam to iterate rapidly and perfect the design, and our extensive network of CNC machinists provided high tolerance and durable parts to spec. This helped SnorriCam bring the latest version of the rig to market quickly and cost-effectively.

Cinephiles and casual moviegoers alike have all seen films with at least a few shots from a SnorriCam. From amplifying the narrative of Darren Aronofsky’s Pi to getting dynamic close-ups of Tom Holland and Zendaya in Spider-Man: No Way Home, the SnorriCam has made its mark on cinematic history.

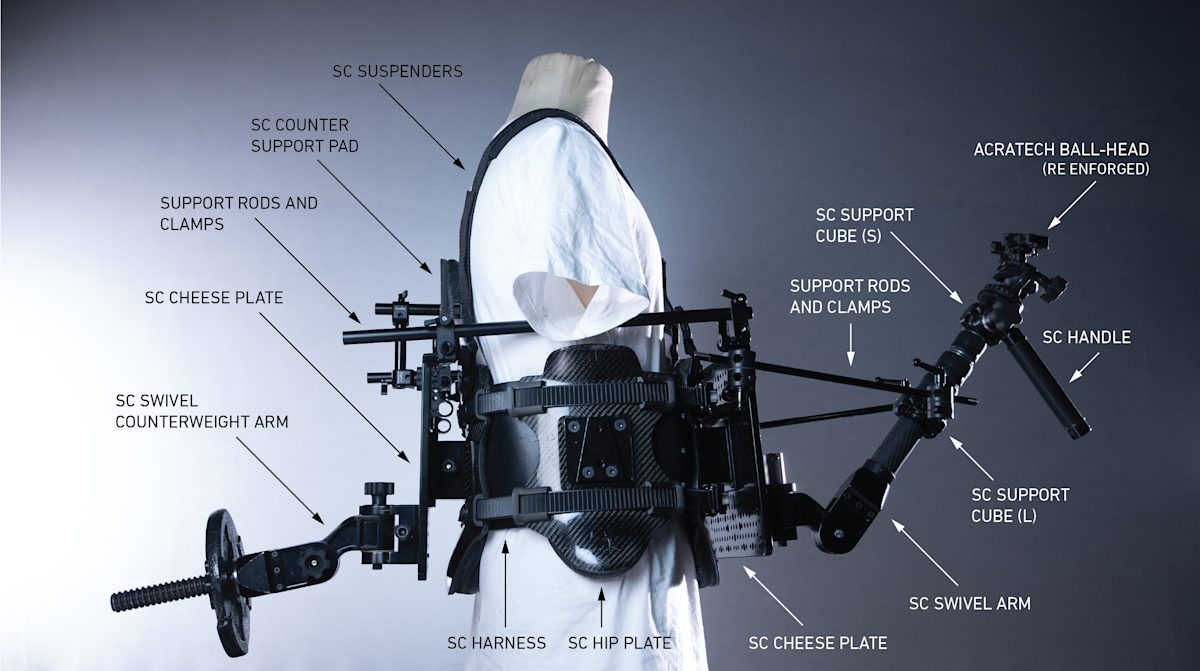

Developed by Eiður Snorri and Einar Snorri in the early 90s, the SnorriCam is a camera rig that attaches to an actor’s body to capture an actor’s point of view. In its current iteration, the rig comprises a standard body harness that can be fitted with many different types of camera arms for different kinds of shots and filming techniques.

To safely attach to an actor’s body, allow for a dynamic range of motion, swivel and lock seamlessly without dropping a 5 kg camera and the SnorriCam rig has to be made of sturdy, highly toleranced stuff. It’s a premium piece of equipment, so every component has to be of professional quality and fit together perfectly while being manufactured in minuscule quantities.

It’s a tall order for traditional manufacturing and a perfect fit for us.

Creating the first SnorriCam

Before developing the SnorriCam, Eiður was a director and filmmaker with no aspirations to become, as he puts it, an “equipment guy.” Any rig he built was for telling stories in a unique way, rather than creating commercial products. So when he and Einar first developed the point-of-view rig that would become the SnorriCam, it was more to “see what a character was feeling.”

The duo was shooting a low-budget music video for a women-led punk band and thought it would be more interesting to get into the heads of the band members through this innovative design.

Eric Watson, a mutual friend of the Snorri’s and burgeoning director Darren Aronofsky, saw the creative potential of the rig and asked to borrow it. Aronofsky ended up using it to film key sequences of Pi (his first film and an award-winner at the 1998 Sundance Film Festival) and according to Eiður, “it ended up being a big part of the look and feel of the film.” The name “SnorriCam” actually comes from Aronofsky himself.

Aronofsky’s cinematic style, amplified by the use of the rig, generated immediate and lasting interest in SnorriCam. Eiður says, “everyone was really interested in this strange camera style.”

The SnorriCam tech and effect soon made the rounds of the indie film world and snowballed into the mainstream. The effect filmmakers are able to achieve by shooting with a SnorriCam even transcended the rig itself. Now called the “SnorriCam effect,” the visual style inspired by the device is still taught in film schools all over the world, with cheaper knockoffs constantly circulating in the market.

“If you’re looking for immersive and energetic shots for your project, you should check out what we have,” says Eiður. “We are the spice for your film.”

Finding the right manufacturer for the SnorriCam

In 2013, Eiður was effectively put out of commission after suffering a bad accident. Prior to this unfortunate turn of events, Eiður and his small team would create and build SnorriCams to rent to friends and filmmaking colleagues, only occasionally exploring its commercial prospects. Two years after the accident, Eiður wanted to get back into the action, but wasn’t recovered enough to direct the way he’d done before. So, he decided to go all-in on SnorriCam.

In professionalizing the idea, Eiður completely restructured the business—effectively starting from scratch on his own—and developed a new version of the rig. He bought a 3D printer, watched a lot of Youtube videos, and started producing a prototype. “I knew exactly what I wanted,” Eiður says. "If you know what you want, you can find a way to make it."

However, building custom rigs as a solo entrepreneur presented a unique manufacturing challenge. Producing professional filmmaking-grade parts would be expensive in small quantities, and design speed was of the essence. Finding traditional manufacturing methods too slow and pricey, Eiður started experimenting with our network's quote builder.

Best supporting manufacturer

Eiður first worked with traditional manufacturers to produce parts for the newly designed rig. This approach meant having to wait several weeks for quotes at an exorbitant cost. Both factors were major hindrances to perfecting the design for use and manufacturability. “It was an impossible process,” says Eiður, who would often drive four hours back and forth to the machine shop.

Wanting to expedite the design process, Eiður turned to us and our free, instant quote builder. The automation and speed of the quote builder, coupled with the ability to upload several CAD designs and compare materials and prices, significantly accelerated Eiður’s ability to innovate. For Eiður’s first six pre-orders, he sourced nearly all of the metal parts from us.

“I realized how amazing this service was to allow small companies like mine to be able to do something like this,” says Eiður. “It’s much more economical and the timeframe is great.”

One of the key benefits of the platform for SnorriCam was its ease of use and design for manufacturability (DfM) support. “I really like that you can upload a CAD file and if there’s something wrong with it, the platform tells you immediately so you can keep uploading new versions until you get the green light,” says Eiður.

Not only have we been able to deliver consistent quality, but the design freedom has also allowed SnorriCam to design proprietary parts without drastically going over budget. “I was able to make certain parts exactly as I wanted to and also save money,” says Eiður.

Presently, we supply all of the metal parts found on the rig, including cheese plates, specialized pins, knobs and wingnuts, arms, swivel mechanisms, support cubes for the arms, and many other complex components. Eiður says, "I don't think I would be able to do this without the network."

Tolerancing for the stars

Many of the SnorriCam parts have critical tolerancing needs. The device itself is a complex harness with an arm supporting a very heavy film camera. “When you swing the camera back and forth, it creates an unbelievable amount of force,” says Eiður, who explains that the camera itself isn’t fixed, but can swivel for a broader range of coverage. “All the locking mechanisms had to be crazy strong to keep the camera from flying all over the place.”

One of the key components of the SnorriCam is a proprietary locking system called the V-Lock, a critical pair of parts that have to fit together accurately. All parts must be tightly toleranced to ensure the entire rig can hold the camera in place and swivel to achieve a variety of camera effects, all while safely harnessed to an actor.

“If they were too loose, the camera would wobble, and if they were too tight, the mechanism wouldn’t fit together,” says Eiður. “You have a very expensive camera at the end of it, so it has to be perfect.”

So though Eiður states that both of his orders through the network so far have arrived on time and within expectation, he admits that he was nervous when he first switched to a digital manufacturing service.

“I had never done this before,” says Eiður. “There are a lot of parts [comprising the SnorriCam rig] and if one thing hadn’t worked, I would have been in deep trouble.”

Next steps for SnorriCam

In 2022, SnorriCam is focusing on improving the professional-grade rig for big-budget productions (expanding its versatility), as well as a potential prosumer device that’s more affordable for smaller production companies and indie filmmakers.

“What we are trying to do with this new rig is make it more versatile,” says Eiður. “We redesigned the rig so it’s now the base of the system, and we can build upon that base.” The new rig can be set up in a myriad of different ways to support heavier and lighter cameras and is easier to wear and move around in. As it’s customizable as opposed to fully custom, the rig can be manufactured in two to three weeks. “And I’m planning to use the nnetwork for almost everything,” says Eiður.

When asked about entering the consumer market, Eiður is staunchly in favor of producing rigs made-to-order, instead of opting for mass-producing them. SnorriCam will likely always be a professional product for serious filmmakers. As Eiður says, “I’m not interested in doing a pure consumer mode. I really want to make things that are premium quality.”

“Giving power to the little guy”

One unique part of SnorriCam’s story is that despite the enormous influence the rig's technology and technique have had in the film industry, the company has always remained small. For now, every rig is made on-demand, though even when the company scales, the vision will always be to put quality first.

SnorriCam doesn’t have a huge company behind it and therefore can’t make millions of parts to balance out the cost of production. With our services, though, SnorriCam can compete with industrial players at this size because it can constantly offer up on-demand rigs for competitive prices with us.

“What’s so great is that it allows small boutiquey people and businesses to compete with giants,” says Eiður, “which is giving power to the little guy. It means a lot”

“I would recommend the network to anyone who wants to make a small number of products but doesn’t have backing,” he says. “I see this as an amazing thing to support creators all over the world.”

Have an innovative product design?

Explore our CNC machining services Get a free, instant quote today