The company:

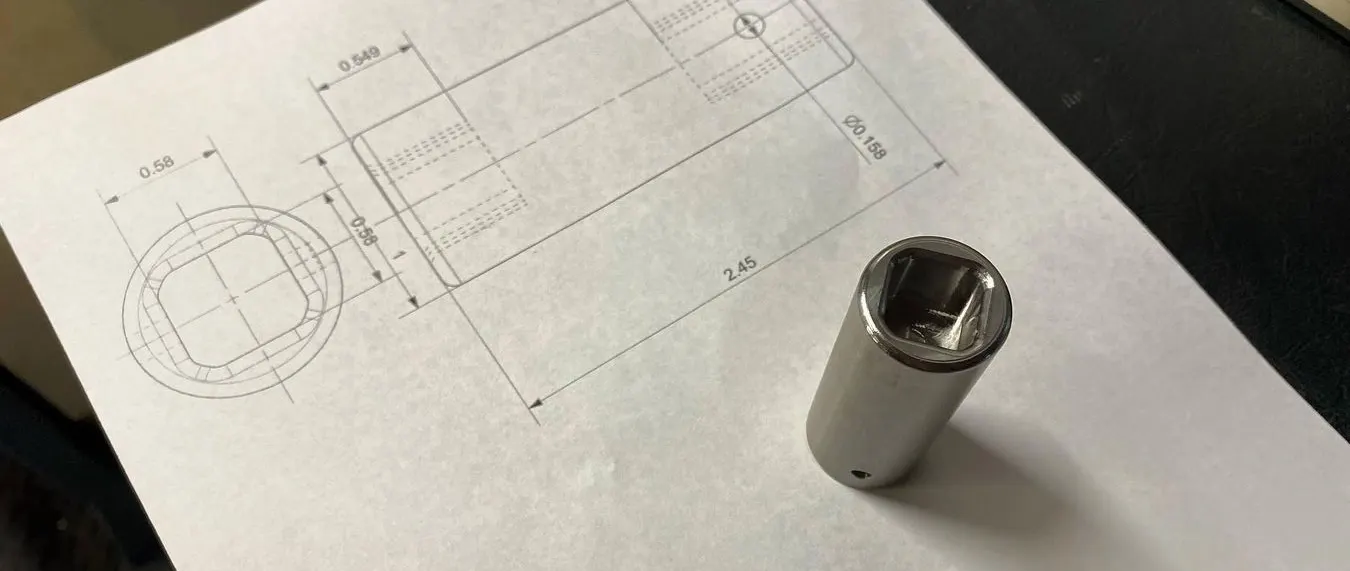

Relic EDC is a Cincinnati, Ohio-based business offering advanced, turnkey CNC machining

Challenge:

Relic strives to create parts with a 100% first-time yield, cutting down on time-consuming back-and-forth and costly iterations

Top priority:

Efficiently and continuously growing a business that serves a niche market

Results:

A 20% increase in revenue since beginning to use our quick-turn, 5-day service

When approached traditionally, orders for CNC-machined parts often require a great deal of back-and-forth, as manufacturers work closely with customers to finalize designs, iterate, and move into production. There are also lengthy negotiating processes, during which days, or even weeks, can pass as both parties come to an agreement.

These processes are both frustrating and costly, with manufacturers often left with downtime that would be better spent in actual production. It’s a challenge faced by most manufacturing companies – and it’s what led Matt Kaser, a former aerospace manufacturing engineer who founded the Cincinnati, Ohio-based Relic in 2014, to join us as a manufacturing partner.

Relic offers an advanced, turnkey CNC machining service, focusing on prototypes and short- to medium-run productions. Since joining our network of manufacturing partners in 2018, Kaser has been able to sidestep complicated negotiation and design processes, accelerating the company’s road to production – and achieving a 20% growth in revenue in the past year.

“It’s the easy factor,” Kaser said. “You just go on the portal and select a job. The price is mostly negotiated, although there’s some wiggle room to come back with a bid. There’s no chasing payment, no going back and forth negotiating. You look at a job, put a bid on it, it’s accepted, you go into production, and 30 days later, you get paid.”

Initially, Kaser saw our platform as a way to fill open capacity, a source of supplementary income for a business that predominantly attracted clients through word of mouth. Once onboarded onto the platform, however, that changed. Business began ramping up, and with the recent introduction of our quick-turn, 5-day service, Relic has enjoyed an influx of orders. As more 5-day lead time projects come in, Relic is able to capitalize even more quickly, spending less time planning and more time producing.

“That’s really helped us grow,” Kaser said. “In the year since they’ve implemented that, we’ve seen a 20% increase in revenue; it’s become a key portion of our business. We’ve invested in more equipment this year based on the workload that’s come through the network. If you’d asked me four years ago, I wouldn’t have thought that would happen.”

Our platform, Kaser said, also helps Relic improve operationally. With more time to focus on production, Kaser can fine-tune his manufacturing processes, resulting in final parts that are of higher quality and more effective – a benefit that overreaches the relationship with us to positively affect all the company’s clients.

“With the network, you’ve very much got to step up your game because the process is so streamlined,” Kaser said. “It’s refined our 100% first-time yield in all aspects of our business because we’re focused on putting out the best proposal possible. There was a learning curve initially because a lot of times you’ll do some post-machining – smoothing or breaking edges or deburring. But if a drawing doesn’t call for it, the customer won’t want it; they want it exactly as described.”

For Kaser and Relic, the past five years have served as an “evolution,” for both his business and his partnership with us, during which platform features have been added, pain points addressed, and processes streamlined. A new feedback feature, for instance, has opened direct yet efficient channels of communication between client and manufacturer, helping Kaser collaborate even more effectively on our projects. These features, Kaser said, along with Relic’s and our network's professional relationship, have set Relic up for long-term success on the platform.