The challenge

PARAFREE is a German startup that develops lightweight, modular wheelchairs for everyday and athletic use. The wheelchair, created by designer Felix Lange, comprises high tolerance, smooth parts for easy assembly and disassembly while maintaining the required strength and durability. In the early days of PARAFREE, Lange and his team were unable to find manufacturers who could deliver these high-strength, production-grade parts in smaller quantities for product testing. Finding the right manufacturing partner was key, especially seeing as the product was a medical device that required as many testing rounds with close-to-end-use parts as possible.

How we helped

Our quote building platform, expert in-house engineers and network of manufacturing partners were able to accelerate PARAFREE’s product development cycle, especially in the functional prototyping stage. Lange and his team used our network to quickly get essential manufacturing details like price, lead time, and material options. This helped them focus on the design, which proved successful as they bagged the esteemed iF Award 2023 in the healthcare category.

Developing a next-generation medical device for every day (and more active) use is no easy feat. One of the major constraints early in the product development process is sourcing parts that tick enough cosmetic and functional quality boxes to emulate how the device will fare in the real world. Finding the right manufacturing partner can be a boon for prototypers that don’t have ample time and finances. This was the case for Felix Lange and his innovative wheelchair startup, PARAFREE.

Designing the next generation of wheelchairs

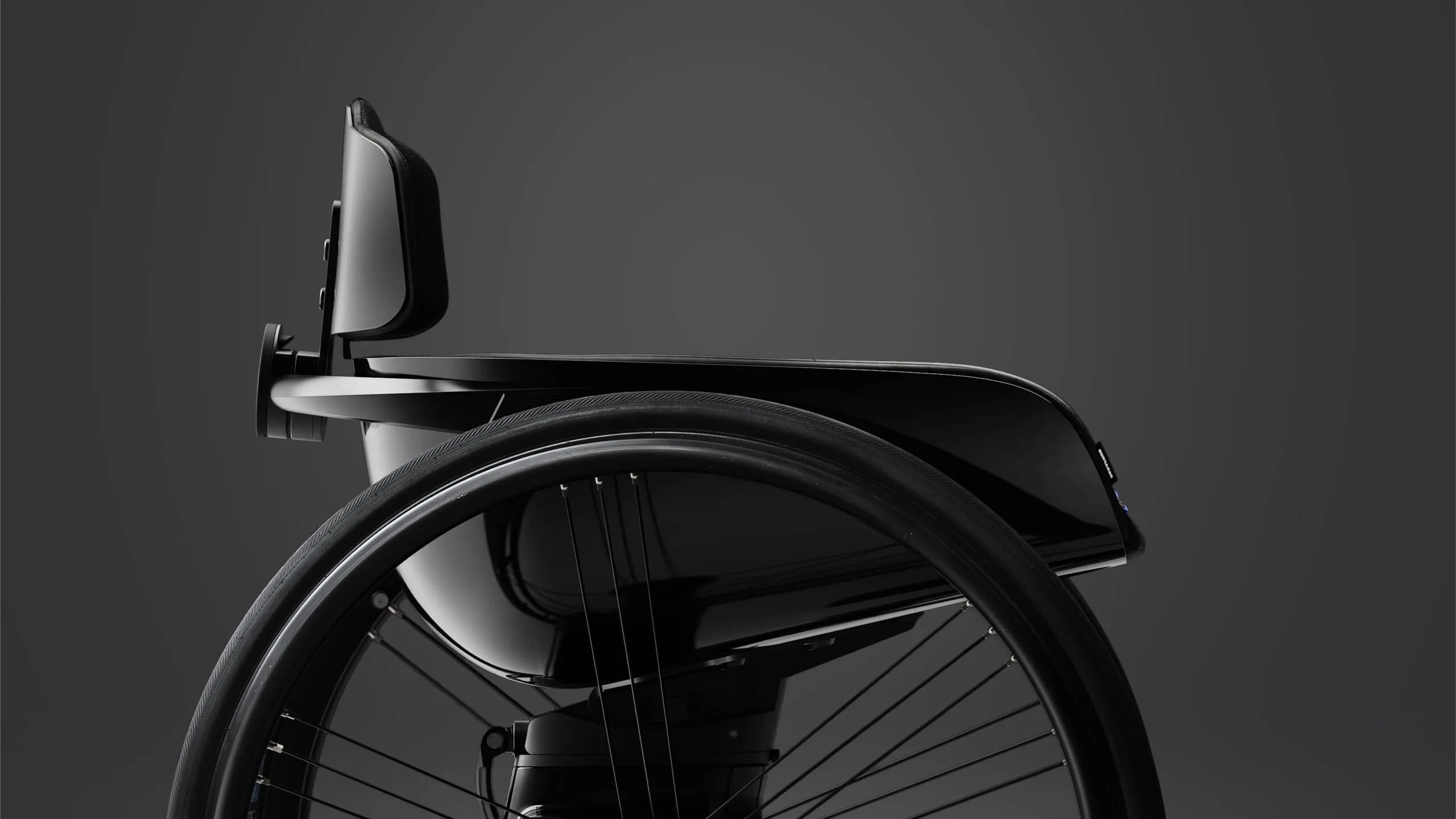

A portfolio company within Langefreunde Design Studio, an agency Lange started in 2012, PARAFREE develops lightweight, modular wheelchairs that can be assembled and disassembled with ease. The product, which Lange first developed as a thesis project in 2011, is designed to give people with limited mobility more flexibility and improve access to athletic activities. It also looks far less utilitarian than other wheelchairs on the market.

“PARAFREE incorporates aesthetically sophisticated design with infinitely variable adjustability,” says Lange. “It turns a tool and necessary aid into a stunning and enriching companion.”

Langefreunde Design Studio is working to enable PARAFREE to grow with the experience of each individual user, with additional components and the ability to disassemble and rebuild the wheelchair easily and quickly.

What medical device innovation is made of

Most of the parts that comprise the PARAFREE wheelchair are made of carbon composite materials, which provide the product’s form, shape and structure, while metal parts provide the core functionality. These parts have to be lightweight, very dimensionally accurate, surface finished for cosmetic and functional smoothness and able to withstand consistent use.

CNC milled aluminum parts have the right material properties required for connecting and adjusting these carbon composite parts, accounting for the wear and tear of frequent wheelchair assembly and disassembly.

One of the key challenges for Lange and his team early on was to find manufacturing solutions for these specific types of robust, high-use components in smaller quantities. “Our biggest challenge was finding a flexible manufacturer that could provide us with the parts required to meet this low-volume production plan,” says Lange.

At first, PARAFREE produced prototyping parts with a local manufacturer, though the design requirements soon exceeded the shop’s available capacity. This augmented costs and, more significantly, caused delays in the design process. Looking for an alternative solution to these manufacturing challenges, Lange and his team decided to test our online platform and distributed network of manufacturing partners.

Building custom parts on demand

Working with our instant quote builder, onboard DFM analysis and in-house engineers considerably sped up PARAFREE’s prototyping process at a reduced cost. Having the quote builder at their disposal offered new design approaches and feedback that allowed Langefreunde to combine parts. As a result, they reduced the wheelchair's weight and cost compared to other small scale series products, without compromising on quality. “The platform gave us live feedback on the manufacturability and potential costs during the development process,” says Lange. “This immediate feedback loop is not attainable when working with traditional manufacturers.”

The network has so far been able to meet all of the production requirements, especially with access to vetted partners operating 5-axis machines and robust SLA 3D printers. Using our platform also helped avoid committing blindly to large orders without getting an indication of the expected quality and functionality.

“The network offers low-volume and single run manufacturing while providing full transparency and control over the production and its costs,” says Lange, “and the engineers have helped us settle on specific production methods and proper materials.”

Lange and his team then used the network for the latest addition to the PARAFREE product, an add-on to the wheelchair with two small wheels for added stability and mobility. Lange wanted to know how feasible the design would be to manufacture via either CNC machining or sheet metal fabrication, and compared both approaches using the Hubs quote builder.

We helped PARAFREE to consolidate all production through one manufacturing partner, simplifying the process so Lange and his team could focus on the work that mattered: perfecting the product and adding innovative attachments to the base design for impressive modularity for all kinds of use-cases.

Lange and his team strive to bring further customization options to this award-winning wheelchair and plan on using our services to manufacture many of these components and add-ons. The goal is to also produce different products, including more medical devices, and Lange is confident that Hubs will remain a viable manufacturing solution for those as well. Their current objective is to increase the accessibility of the product by scaling up, and they are open to collaborations.

“Every young designer dreams of changing the world with a product that improves people’s lives,” says Lange. “They have given us reassurance in the way we design our parts, and certainty that we are doing it right.”