“When I saw on the website you just had to drag and drop your 3D file to get an instant quote, I was seriously blown away,” - Ty Tatro, Co-founder and Lead Desiger at Redtail Overland

| Organization | Redtail Overland |

|---|---|

| Industry | Recreational vehicles, camping |

| Technology | 3D printing (FDM), CNC machining |

| Materials | PLA, Aluminum 6061-T6 |

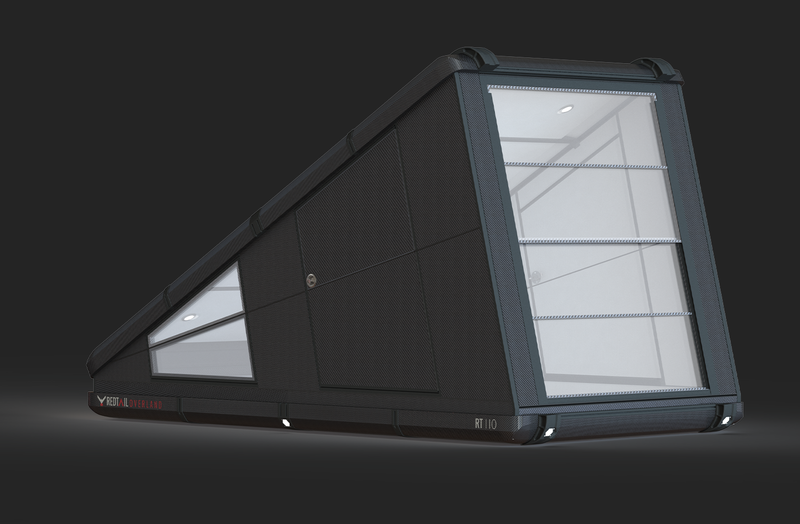

Currently in the process of creating the production quality prototype, Redtail Overland is building a rooftop camper that perfectly balances convenience with comfort.

Ty and Annie Tatro, co-founders of Redtail Overland, found large RV’s and vans too heavy, too expensive, and required far too much maintenance, while conventional rooftop tents can be cold, basic and wet.

They wanted to make a rooftop camper that could offer the freedom of a rooftop tent, but the comfort of a larger camper, with built in heating, charging and ample space.

Minimizing costs with fewer prototyping rounds

Instead of jumping into physical prototypes, lead designer Ty wanted to reduce time and costs by investing more time on the digital design, going through multiple design iterations on SolidWorks over the span of 9 months.

These iterations also included some crude physical prototyping with foam to get an idea of the shape, as well as a dimensionally accurate, functional prototype made from aluminum and wood.

The two main considerations that steered the decisions of the design were weight and aesthetics. Weight because the camper needs to be light enough to sit on top of a van or SUV’s roof, and aesthetics because Ty and Annie want the final product to appeal to a luxury, high end market.

Key features of the camper include:

- Carbon fiber construction to save around 30% of weight over fiberglass and 50% over aluminum

- Foam carbon fiber composite for the outer panels, which provide a good level of insulation while still being very lightweight

- Roof rack is built into the camper, saving additional weight and for a sleeker aesthetic

- Large solar panel array and lightweight, lithium ion battery bank

- Dual pane, polycarbonate system for the windows

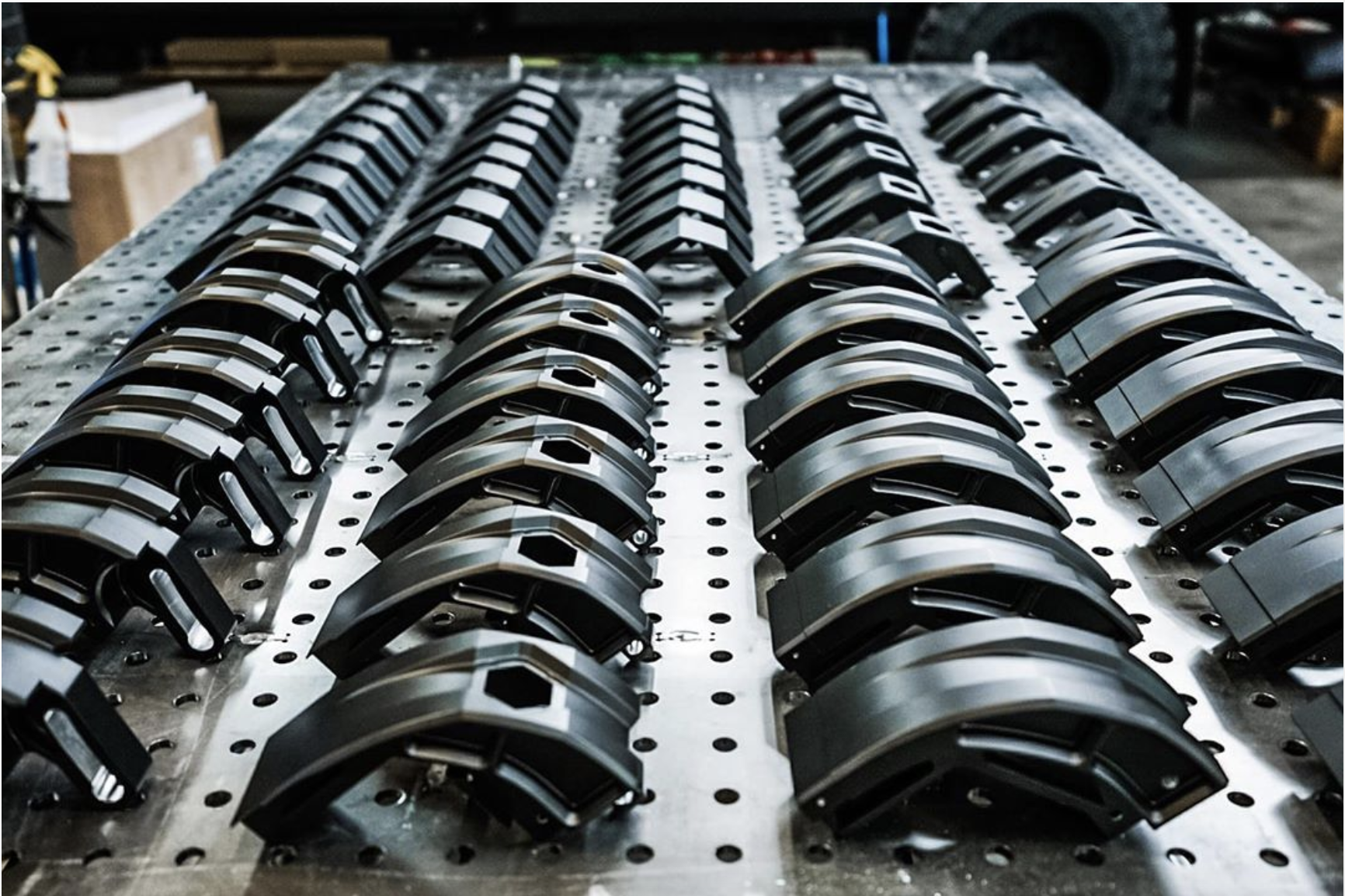

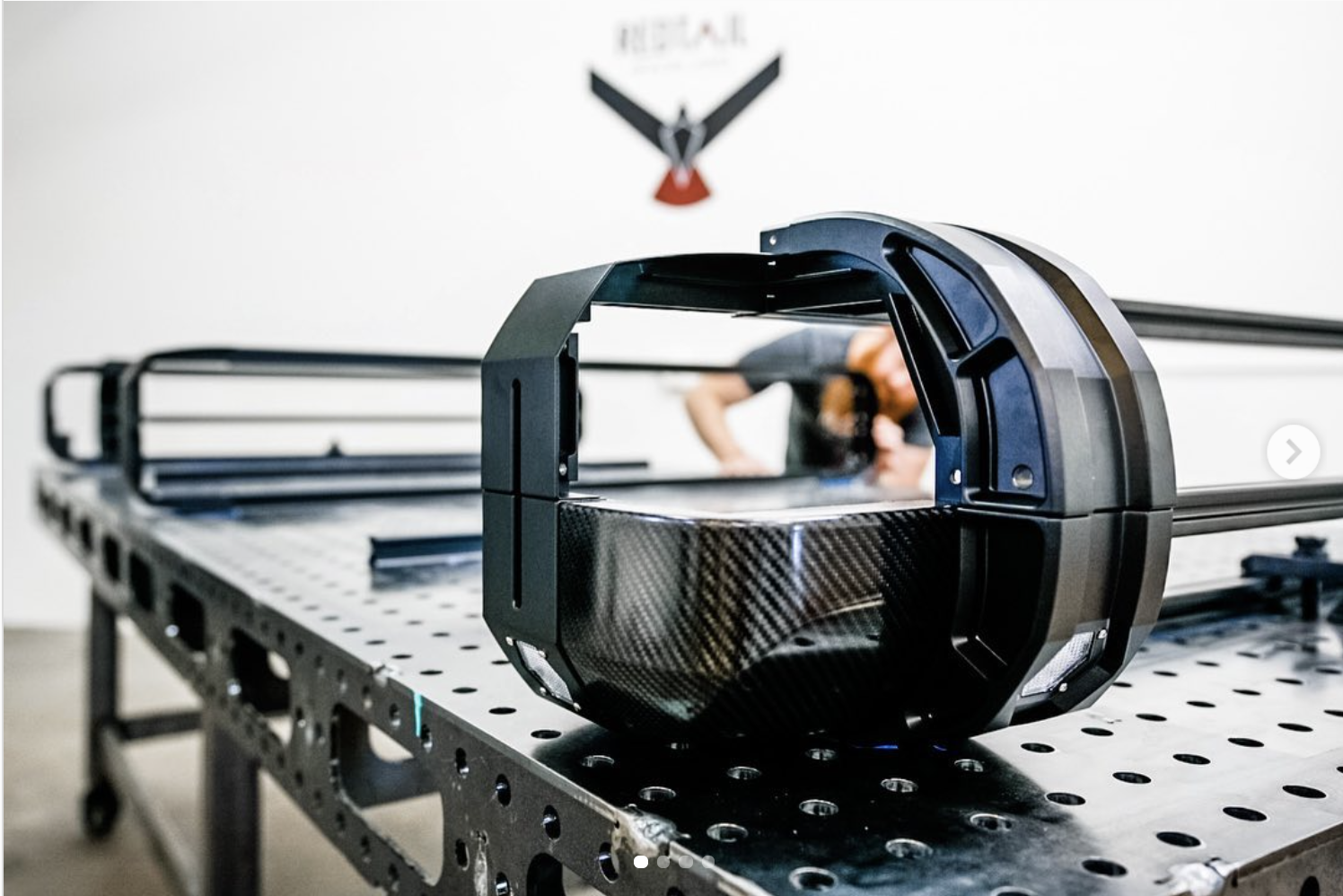

“The original prototype was all square corners,” shares Ty, “so we’re using these aluminum brackets to create that contoured profile that has a radius in it and chamfered edge and it gives the design some character.”

“We were just going to get the products produced out of aluminum but we thought if we could 3D print them for pretty cheap, then we could verify the design,” he adds, “And as long as we did that we felt comfortable ordering 3 campers’ worth of the aluminum parts instead of just one, which with the higher quantity would save us a bunch of money per unit.”

FDM is a great cost-effective way to produce prototypes and has a wide range of thermoplastic materials available, including PLA, which provides high stiffness and a good level of detail.

“I’m trying to leverage 3D printing in any way we can and try and not do things how they’ve been done traditionally for so long,” explains Ty.

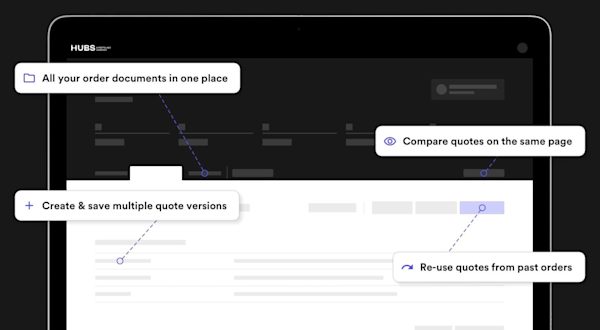

Instant quoting to speed up design & reduce costs

Ty describes the worst part of his previous job as getting any sort of machined part quoted, especially during the prototyping phases, as you’d have no idea how much it would cost and to get an idea you’d have to spend a lot of time putting together technical drawings.

“So when I saw that ont the website you just had to drag and drop your 3D file to get an instant quote, I was like no way, and I did it and I was seriously blown away,” he remembers, “It took only a minute to get the price and I could play around with what it would cost if I did it out of something like titanium. I could select all these things just to see.”

Ty shared he’d usually feel awkward approaching traditional machining shops and asking for so many quotes, but now he could compare the price of different materials, as well as adjust his design to see how the changes would affect the cost.

“I had certain fillets and radiuses in different areas and it was really cool to eliminate some features and add some features and see how that affected the cost in a way that would make it easier to machine and bring the cost down,” explains Ty.

Read more customer stories: