Fast & affordable prototyping

-

Dimensional accuracy of ± 0.5% with a lower limit: ± 0.5 mm

-

Lead times from 1 business day

Source high-quality parts for prototyping and production easily using selective laser sintering (SLS) 3D printing. Select from industrial-grade materials and a broad range of surface finishes. Our standard lead time is just 3 business days.

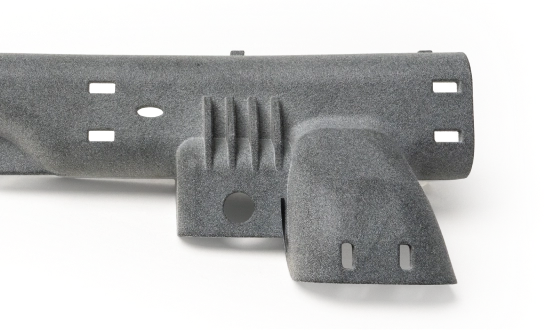

Selective Laser Sintering (SLS) is an industrial 3D printing process that is ideal for manufacturing end-use parts. In SLS, a laser selectively sinters polymer powder particles, fusing them together and building a part layer-by-layer. With some of the largest print beds, SLS machines can produce functional plastic parts with isotropic mechanical properties for detailed prototyping or high-volume production orders of end-use parts. SLS is a cost-efficient production method, which our customers regularly choose for the most complex parts and those requiring extensive customization.

Learn more about SLS 3D printing

| Maximum build size | Standard lead time | Dimensional accuracy | Layer thickness | Minimum feature size |

|---|---|---|---|---|

| 395 x 500 x 395 mm (15.53" x 19.68" x 15.53") | 3 business days | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012 in) | 100μm | 0.5 mm (0.0196”) |

SLS 3D printing uses robust powder materials that are ideal for functional prototyping and low- to-medium volume production of end-use parts.

| Material | Color | Resolution | Tensile strength | Elongation at break | Heat deflection temperature | Application |

|---|---|---|---|---|---|---|

| Nylon (PA 12) | White, dyed black | 100 μm | 41-50 MPa | 11-36% | 146-180 °C | Prototypes, detailed and complex parts, fully functional models, and end products. |

| Glass-filled Nylon (PA 12)(US only) | Off-white | 100 μm | 30-48 MPa | 6.3-9.3% | 152-179 °C | Enclosures and housings, jigs, fixtures, tooling |

Improve the mechanical properties and aesthetic features of your SLS 3D-printed parts with these post-processing options.

Typically white or stone gray, smooth surface, powder texture, without visible layers.

Dyed black by immersion in a warm color bath. The color penetration reaches a depth of about 0.5 mm and covers all surfaces.

The parts are placed in a tumbler that contains small ceramic chips, gradually eroding its surface down to a polished injection molding-like finish.

| Materials | Price | Dimensional accuracy | Strengths | Build volume | Layer thickness | Min. feature size | |

|---|---|---|---|---|---|---|---|

| FDM | 5 | $ | ± 0.5% with a lower limit on ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 100-300μm | 2.0 mm (0.0787’') |

| Industrial FDM | 6 | $$$$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012") | High level of repeatability, engineering grade materials | 406 x 355 x 406 mm (15.98” x 13.97” x 15.98") | 100-330μm | 2.0 mm (0.0787’') |

| Prototyping SLA | 8 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012") | Smooth surface finish, fine feature details | 145 × 145 × 175 mm (5.7" x 5.7" x 6.8") | 50-100μm | 0.2 mm (0.00787’') |

| Industrial SLA | 3 | $$$ | ± 0.2% with a lower limit of ± 0.13 mm (± 0.005") | Smooth surface finish, fine feature details, big print area | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 50-100μm | 0.2 mm (0.00787’') |

| SLS | 2 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) | Design flexibility, supports not required | 395 x 500 x 395 mm (15.53" x 19.68" x 15.53") | 100μm | 0.5 mm (0.0196”) |

| MJF | 2 | $$ | ± 0.3% with a lower limit on ± 0.3 mm (0.012’') | Design flexibility, supports not required | 380 x 285 x 380 mm (14.9’’ x 11.2’’ x 14.9’') | 80μm | 0.5 mm (0.0196”) |

We manufacture your custom parts according to strict manufacturing standards and ensure all parts and processes adhere to the Protolabs Network Standard. A thorough verification of these requirements is included in our inspection report that we ship with every order.

After printing, parts are bead blasted and then air blasted to get rid of the excess powder on the surface.

Additional post-processing can be done to improve part’s appearance, such as dyeing, vapor smoothing or tumbling.

No support material is needed

Excellent layer adhesion

Fast printing process for functional, durable prototypes or end-use parts

Materials have good mechanical properties

As-printed parts are rough to the touch due to surface porosity

SLS is prone to shrinkage and warping, especially on long, thin parts

The table below summarizes the recommended and technically feasible values for the most common features encountered in SLS 3D printed parts.

Read more about how to design for SLS 3D printing

| Feature | Recommended size |

|---|---|

| Unsupported walls | 1.0 mm (0.040 in) |

| Supported walls | 0.8 mm (0.031 in) |

| Minimum detail size | 0.8 mm (0.031 in) |

| Minimum hole size | 1.0 mm (0.040 in) |

| Moving parts | 0.5 mm (0.020 in) |

| Assembly clearance | 0.4 mm (0.016 in) |

| Maximum wall thickness | 20 mm (0.8 in) |

Learn more about how SLS 3D printing works and how to design the best parts for this additive manufacturing technology.

| Want to learn more about SLS? |

|---|

Fast & affordable prototyping

Dimensional accuracy of ± 0.5% with a lower limit: ± 0.5 mm

Lead times from 1 business day

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

See our MJF services

Visual prototyping

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

See our SLA services