SLA 3D printing service

Source high-performing parts for rapid prototyping and production with Protolabs Network's SLA 3D printing service. We offer tons of prototyping and industrial resin materials and can print parts in as little as 1 day.

What is SLA 3D printing?

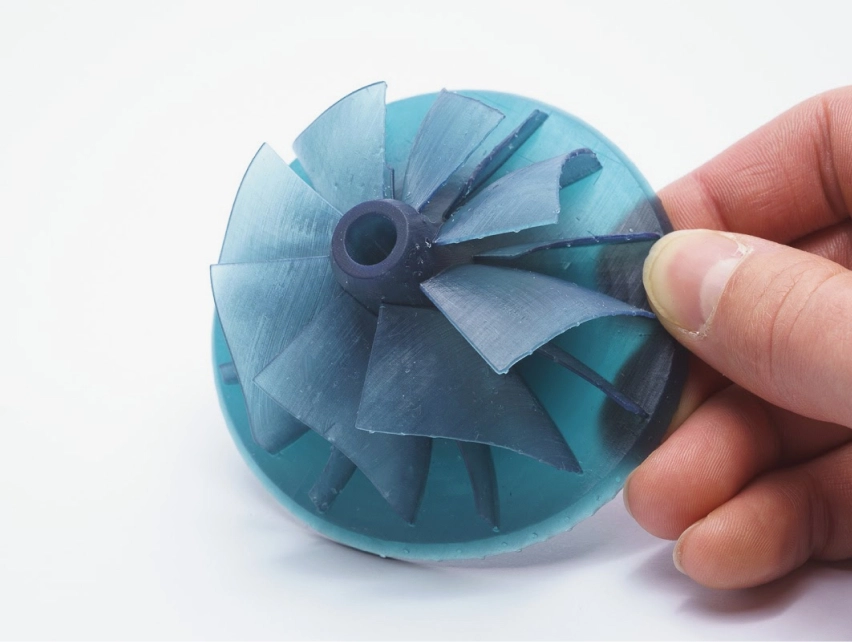

Stereolithography (SLA), also known as resin 3D printing, is a 3D printing technology that produces parts with high resolution and accuracy, fine details and smooth surface finishes. Part of the vat photopolymerization printing family, SLA technology uses photosensitive thermoset polymers to produce custom parts. We use Formlabs materials for rapid prototyping and 3D Systems Accura materials for large-scale production.

Learn more about SLA 3D printing

SLA 3D printer capabilities

SLA 3D printing has two distinct classes: prototyping (desktop) SLA and industrial SLA. These are the key capabilities of each technology.

| Maximum build size | Standard lead time | Dimensional accuracy | Layer height | Minimum feature size | |

|---|---|---|---|---|---|

| Prototyping (desktop) SLA | 145 × 145 × 175 mm (5.7 in x 5.7 in x 6.8 in) | From 3 business days | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012") | 50-100 μm | 0.2 mm |

| Industrial SLA | 500 x 500 x 500 mm (19.68 in x 19.68 in x 19.68 in) | From 3 business days | ± 0.2% with a lower limit of ± 0.13 mm (± 0.005") | 50-100 μm | 0.2 mm |

SLA 3D printed parts come in many materials

Leading companies and engineers that need to iterate quickly or get strong industrial plastic parts faster use Protolabs Network for our range of prototyping and production materials.

Ideal for accurate visual prototypes with smooth surface finishes.

Formlabs Standard Resin

Formlabs Grey

Pro Resin

Formlabs Clear Resin

Formlabs Durable Resin

Formlabs High Temp Resin

Formlabs Flexible Resin 80A (US only)

Formlabs Tough Resin 2000

Formlabs Rigid Resin 4000

Ideal for durable functional prototypes and high precision parts with smooth surface finishes.

Accura ClearVue

Accura Xtreme White 200

Accura 25

Post-processing for SLA

Standard (no additional post-processing)

-

All support material is removed and support nibs are sanded smooth.

-

For clear resins, a polishing oil is applied.

-

Formlabs materials are cured in a Form Cure using the following settings which follow the official Formlabs “Recommended Cure” settings.

Formlabs Cure settings

| Resin | Post-cure time | Post-cure temperature |

|---|---|---|

| Standard clear | 15 min | 60 °C |

| Standard black | 30 min | 60 °C |

| Standard white | 30 min | 60 °C |

| Standard gray | 30 min | 60 °C |

| Tough 2000 | 60 min | 70 °C |

| Durable | 1 hour | 60 °C |

| Grey pro | 15 min | 80 °C |

| High temp | 2 hours | 80 °C |

| Flexible | 15 min | 60 °C |

| Rigid | 15 min | 80 °C |

How SLA stacks up against other 3D printing technologies

| Materials | Price | Dimensional accuracy | Strengths | Build volume | Layer thickness | Min. feature size | |

|---|---|---|---|---|---|---|---|

| FDM | 5 | $ | ± 0.5% with a lower limit on ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 100-300μm | 2.0 mm (0.0787’') |

| Industrial FDM | 6 | $$$$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012") | High level of repeatability, engineering grade materials | 406 x 355 x 406 mm (15.98” x 13.97” x 15.98") | 100-330μm | 2.0 mm (0.0787’') |

| Prototyping SLA | 8 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012") | Smooth surface finish, fine feature details | 145 × 145 × 175 mm (5.7" x 5.7" x 6.8") | 50-100μm | 0.2 mm (0.00787’') |

| Industrial SLA | 3 | $$$ | ± 0.2% with a lower limit of ± 0.13 mm (± 0.005") | Smooth surface finish, fine feature details, big print area | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 50-100μm | 0.2 mm (0.00787’') |

| SLS | 2 | $$ | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) | Design flexibility, supports not required | 395 x 500 x 395 mm (15.53" x 19.68" x 15.53") | 100μm | 0.5 mm (0.0196”) |

| MJF | 2 | $$ | ± 0.3% with a lower limit on ± 0.3 mm (0.012’') | Design flexibility, supports not required | 380 x 285 x 380 mm (14.9’’ x 11.2’’ x 14.9’') | 80μm | 0.5 mm (0.0196”) |

We have high standards for SLA 3D printing

We manufacture your custom parts according to strict manufacturing standards and ensure all parts and processes adhere to The Protolabs Network Standard. A thorough verification of these requirements is included in our inspection report that we ship with every order.

-

Parts are fully cured to material manufacturer specifications before shipping.

-

Hollow sections are drained of excess resin.

-

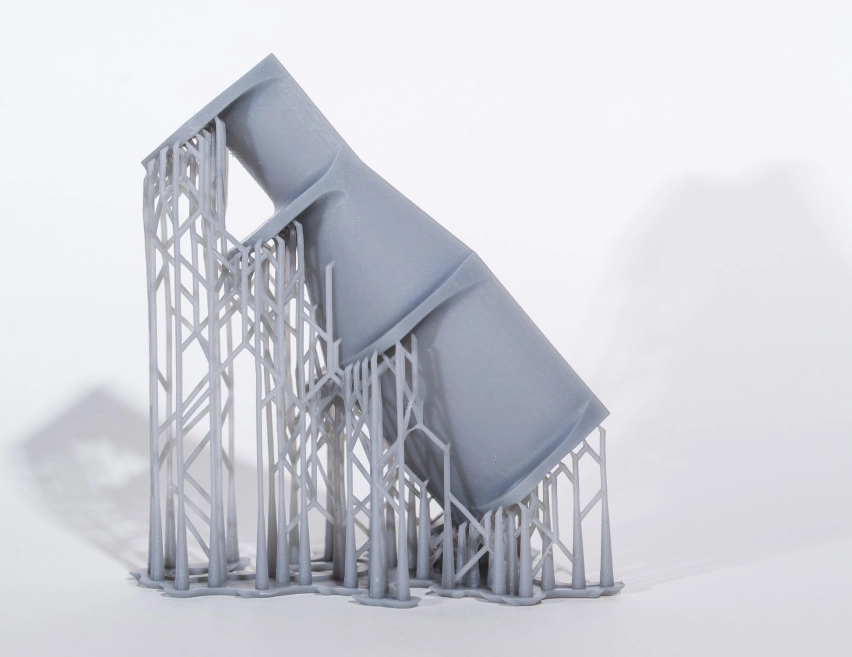

All support material is removed and support nibs must be sanded smooth.

Advantages and drawbacks of SLA 3D printing

-

SLA can produce parts with very high dimensional accuracy and intricate details.

-

SLA parts have a very smooth surface finish, making them ideal for visual prototypes.

-

Speciality SLA materials are available, such as clear, flexible and castable resins.

• SLA parts are generally brittle and not suitable for functional prototypes, though industrial SLA can produce more functional components for this stage.

• The mechanical properties and visual appearance of SLA parts will degrade over time when the parts are exposed to sunlight.

• Support structures are always required and post-processing is necessary to remove the visual marks left on the SLA part.

Design guidelines for SLA

3D printing

This table summarizes the recommended and technically feasible values for the most common features of SLA 3D printed parts.

Read more about how to design for 3D printing

| Feature | Recommended size |

|---|---|

| Unsupported walls | 1.0 mm (0.0393 in) |

| Supported walls | 0.5 mm (0.0197 in) |

| Minimum feature size | 0.2 mm (0.00787 in) |

| Minimum hole diameter | 0.5 mm (0.0197 in) |

| Minimum escape hole diameter | 4.0 mm (0.157 in) |

More resources for SLA

3D printing

Learn more about how SLA 3D printing works and how to design parts for this adaptive additive manufacturing technology.

| Introductory guides |

|---|

Our other 3D printing processes

Fast & affordable prototyping

-

Dimensional accuracy of ± 0.5% with a lower limit: ± 0.5 mm

-

Lead times from 1 business day

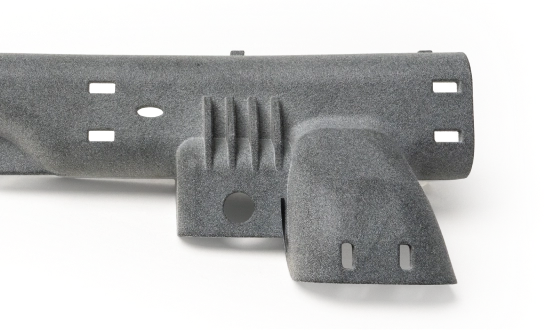

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

See our MJF services

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

See our SLS services